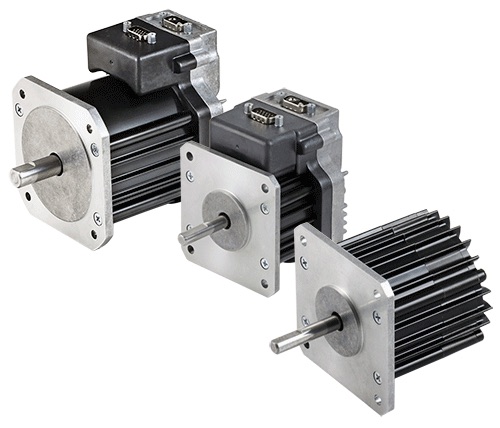

Brushless DC Motors - RapidPower™ Xtreme Brushless DC

Brushless Dc Motor for sale - eBay Things To Know Before You Get This

As the rotor turns, the commutator selects various windings and the directional current is used to an offered winding such that the rotor's magnetic field stays misaligned with the stator and creates a torque in one instructions. Downsides of commutator [modify] The commutator has disadvantages that has resulted in a decrease in usage of brushed motors.

The soft brush product wears down due to friction, producing dust, and eventually the brushes should be replaced. This makes commutated motors inappropriate for low particulate or sealed applications like hard drive motors, and for applications that need maintenance-free operation. The electrical resistance of the sliding brush contact causes a voltage drop in the motor circuit called brush drop which consumes energy.

During the last a century, high-power DC brushed motors, when the pillar of industry, were changed by rotating existing (AC) simultaneous motors. Today, brushed motors are just utilized in low power applications or where only DC is available, but the above drawbacks limit their usage even in these applications. Brushless solution [modify] In brushless DC motors, an electronic servo system replaces the mechanical commutator contacts.

The Best Guide To Brushless DC Motor (BLDC Motor) Speed Control Systems

The elimination of the moving contact allows brushless motors to have less friction and longer life; their working life is only limited by the lifetime of their bearings. Brushed DC motors establish an optimum torque when stationary, linearly decreasing as speed boosts. Click Here For Additional Info of brushed motors can be gotten rid of by brushless motors; they consist of higher performance and lower susceptibility to mechanical wear.

A typical brushless motor has long-term magnets that rotate around a fixed armature, eliminating issues related to linking present to the moving armature. An electronic controller replaces the commutator assembly of the brushed DC motor, which constantly switches the stage to the windings to keep the motor turning. The controller carries out comparable timed power circulation by utilizing a solid-state circuit instead of the commutator system.

With no windings on the rotor, they are not subjected to centrifugal forces, and because the windings are supported by the real estate, they can be cooled by conduction, needing no airflow inside the motor for cooling. This in turn implies that the motor's internals can be completely enclosed and protected from dirt or other contaminant.

UNDER MAINTENANCE